Uncategorized

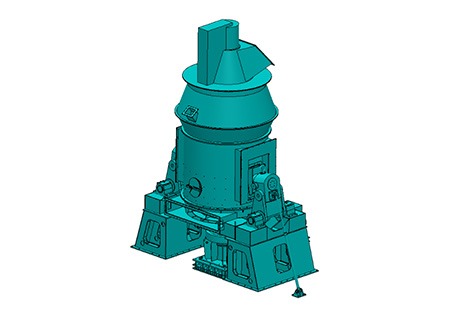

HRM1900 vertical mill

Description

Overview: The HRM1900 vertical mill is a technically superior drying and grinding machine primarily used for grinding cement raw materials, but can also be widely used in the building materials, light industry, chemical industry, and thermal power generation industries. This mill offers high grinding efficiency, low power consumption, large feed size, easily adjustable product fineness, a simple process flow, a compact footprint, low noise levels, minimal dust generation, easy operation and maintenance, low operating costs, and minimal consumption of wear-resistant materials. Furthermore, this mill boasts the following unique features: 1. The grinding rollers can be hydraulically tilted out of the mill, providing ample space for replacing roller sleeve liners and mill maintenance, making maintenance extremely convenient. 2. The roller sleeves can be flipped over, extending the service life of the wear-resistant material. 3. No material needs to be placed on the grinding disc before startup, and the mill can be started without load, eliminating the hassle of startup. 4. A roller limiter prevents severe vibration caused by material breakage during mill operation. 5. 6. The grinding roller bearings are oil-immersed, eliminating the need for external circulation lubrication. 7. The external circulation system reduces wind speed at the air ring, reduces vertical mill exhaust fan power, improves mill startup and shutdown conditions, and reduces maintenance cleaning time.

The working principle is as follows: The motor drives the reducer, which rotates the grinding disc. The material to be ground is fed into the center of the rotating grinding disc by an air-locked feeding device. Centrifugal force moves the material toward the periphery of the grinding disc and into the grinding rollers. The hydraulic pressure of the grinding rollers compresses, grinds, and shears the material, pulverizing it. Simultaneously, hot air is ejected upward at high speed from an air ring surrounding the grinding disc. The high-speed airflow from the air ring lifts the ground material, blowing the coarser material back to the grinding disc for re-grinding and drying any suspended material. The hot air then carries the fine powder to a separator for classification. Qualified fine powder exits the mill along with the airflow and is collected by a dust collector as the final product. Unqualified coarse powder falls back to the grinding disc under the action of the separator blades and is re-ground with the newly fed material. This cycle completes the entire grinding process.

Technical parameters and performance 1. Main technical parameters Specification model: HRM1900 Grinding disc middle diameter: φ1900 Grinding roller diameter: φ1500mm Grinding roller number: 2 Grinding disc speed: 37r/min Maximum feed particle size: ≤30mm Moisture content of feed material: ≤13% Product fineness: 200 mesh (sieve residue 10%) Output: 35-45t/h Product moisture content: ≤5% Inlet air temperature: <250℃ Outlet air temperature: 65~70℃ Outlet air volume: 120000m3/h Mill pressure drop: 5000~7000Pa Hydraulic system working pressure: ≤12Mpa Mill overall dimensions: Length: 5210mm Width: 3163mm Height: 8495mm Total weight of mill: 100000kg 2. Main motor model: Y450-6 Power: 500KW Speed: 990r/min Voltage: 6KV Protection level: IP23 ㈢. Main reducer Manufacturer: Chongqing Gearbox Co., Ltd. Model: VBP500 Quantity: 1 unit Transmission power: 500kW Motor power: 500kW Speed ratio: 26.757 Rotation direction: When viewed from above, the thrust plate rotates clockwise. Lubricating oil inlet and outlet pipes are lateral: When standing at the input shaft end facing the reducer, the two oil inlets and one oil outlet are both on the left side of the reducer. Transmission efficiency: ≥98%