LCA

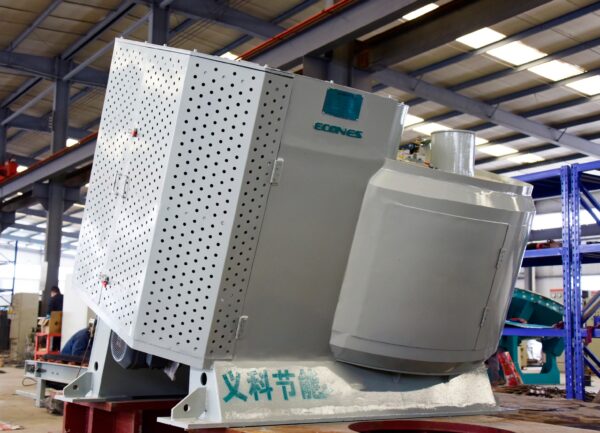

Glass powder mixing and granulation machine

Description

The intermittent mixing and granulating machine is suitable for batch granulation processes after mixing various powdered materials with additives, such as desiccant, foamed ceramics, iron powder granulation, glass powder granulation and seed coating granulation processes. It can achieve rapid mixing, good uniformity, good fluidity, fine particle size and high strength.

Uses and features:

It is suitable for batch granulation process after mixing glass powder with other powders and additives, and can achieve fast and uniform mixing, good uniformity, good fluidity, high particle size and high strength.

Features of intermittent granulator:

1. Rapid granulation : Intermittent granulation uses an external drum and an internal high-speed rotating rotor to simultaneously stir the powder in a high-speed reverse direction. Under the dual action of the flow field and liquid additives, granulation is quickly achieved. By adjusting the additive content, stirring time and frequency, the particle size distribution can be fine-tuned.

2. High granulation rate and high strength : The granulation rate of the intermittent mixing and granulating machine can reach up to 95%, with dense particles and high strength;

3. Wear-resistant and anti-corrosion : Wear-resistant and anti-sticking linings are installed on all wear parts of the equipment. This can effectively extend the service life of the high-speed motion mechanism and reduce power loss;

4. Automatic control : PLC can be used to achieve central and remote control and fully automatic operation to avoid errors caused by manual operation; users can automatically complete granulation by pre-setting the mixing, water addition, and drug addition sequence and dosage.

Application Areas

It is mainly suitable for industries that require mixing and granulation, such as ceramics, tiles, mosaics, refractory materials, chemicals, food, light industry, slag, etc.

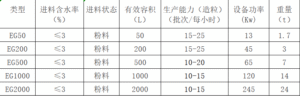

Technical Parameters

Note: Production capacity varies with different particle process requirements