LCA

Filter mud remover

Description

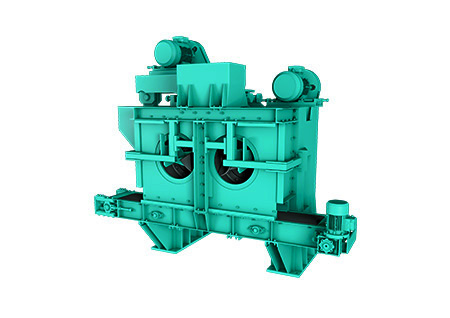

Roller Filter is a device for purifying wet sticky black mud containing impurities

.

Roller filter is an equipment which can remove the impurity from black clay.

Automatic reset: When large debris in the wet and sticky black mud passes through the gap between the grinding rollers, the moving roller swings in the opposite direction, the distance between the moving roller and the static roller increases, the debris falls, and the moving roller automatically resets under the action of its own spring force;

Auto-reset: when the large debris of black clay pass through the roller gap, the action roller swing in the opposite direction. Debris falling caused by the larger distance between the action roller and static roller. So under the action of spring force, the action roller automatic reset.

Energy saving and consumption saving: the overall installed power of the equipment is very low, which makes the equipment itself very effective;

Energy-efficient: Overall equipment installed power is very low, making the useful effect of equipment itself is very high.

High-tech: Using advanced foreign technology, which is rarely found in China.

High-tech: Using advanced foreign technology, the only unique technology in our country.

Convenient for subsequent processing: The sludge after filtering and removing impurities from the sludge filter is divided into mud strips, which is conducive to subsequent sludge drying, crushing and grinding.

subsequent process: After removed from the roller filter of sludge, can be divided into clay strips, which is favorable for subsequent sludge drying, crushing and grinding.

Technical principle Work principle

Irregular wet, sticky black mud is rolled by the rollers into shaped strips. Scrapers scrape the strips that pass through the conical holes and transfer them to the next process. Impurities in the wet, sticky black mud, such as stones, branches, and metal objects, are too large to pass through the roller holes. The movable rollers swing away from the fixed rollers, causing these impurities to fall onto the belt below.

The black clay, filtered in uniform sizes by means of suitable conveying scrapers fitted inside the rollers, is separated in thin layers. This allows to have an efficient mixing and a better homogeneity of the clay that will be then sent to the following machines through a conveyor built in proper hoppers. The presence of impurities as stones, roots, metal bodies etc., bigger than the holes of the rollers will cause the shifting of the movable roller which moving away from the fix one, will allow their passage and the conveyance to a belt conveyor fitted underneath.Application

fields

It is mainly suitable for industries that require sludge treatment, such as ceramics, tiles, refractory materials, medicine, chemicals, food, and sewage treatment plants.

Ceramics, tiles, refractory materials, medicine, chemical, foodstuff, sewage station and so on.

Technical Parameters

| Type Model |

Input state |

Capacity ( m³/h) |

Roller diameter (mm) |

Equipment powerMoter power(Kw) |

Weights (t) |

| 145FC | Black clay | 30-50 | 1450 | 44 | 10 |

| 182FC | Black clay | 50-80 | 1600 | 44 | 13.5 |

| 208FC | Black clay | 80-100 | 2000 | 110 | 16.5 |