LCA

Ceramic brick and tile raw material dry preparation system

Description

Yike’s dry-process preparation technology, technologies, and equipment for ceramic wall and floor tile raw materials are industry leaders, fully independently developed and possess proprietary intellectual property rights. Yike boasts core technological advantages in automated mixing, homogenization, humidification granulation, fluidized bed drying, and particle optimization. The ceramic powder produced using Yike’s dry-process pulverization process perfectly meets diverse customer requirements in terms of grind fineness control, homogenization, particle grading, and bulk density adjustment. Product quality rivals that of traditional wet-process

Yike’s dry-process preparation technology, technologies, and equipment for ceramic wall and floor tile raw materials are industry leaders, fully independently developed and possess proprietary intellectual property rights. Yike boasts core technological advantages in automated mixing, homogenization, humidification granulation, fluidized bed drying, and particle optimization. The ceramic powder produced using Yike’s dry-process pulverization process perfectly meets diverse customer requirements in terms of grind fineness control, homogenization, particle grading, and bulk density adjustment. Product quality rivals that of traditional wet-process

methods .

Key advantages include a small footprint, low investment, high automation, minimal labor, and ultra-low environmental emissions. Raw material preparation costs can be reduced by over 60% compared to wet-process methods.

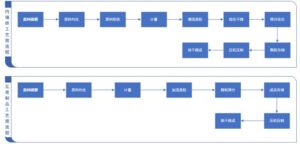

Process diagram

Example pictures